Shandong Horizon Machinery Co., Ltd

Scrap Metal Processing Machines Built for Heavy-Duty Performance

Looking for the Ultimate Solution to Scrap Metal Handling? Maximize Recycling Efficiency with Our Full Range of Industrial-Grade Equipment

- Scrap Metal Baler

- Scrap Metal Magnet

- Alligator Shear

- Gantry Shears

Shandong Horizon Machinery Co., Ltd

Scrap Metal Processing Machines Built for Heavy-Duty Performance

Looking for the Ultimate Solution to Scrap Metal Handling? Maximize Recycling Efficiency with Our Full Range of Industrial-Grade Equipment

- Scrap Metal Baler

- Scrap Metal Magnet

- Alligator Shear

- Gantry Shears

Our Products

Whether you run a recycling plant or a scrap yard, inefficient equipment can cost you time, money, and market opportunities. That’s where we come in.

Scrap Metal Magnets

China professional Scrap Metal Processing Machines factory

Our machines have been trusted by scrap yards, recycling plants, demolition companies, and metal processors in over 50 countries. Parts within the quality warranty period will be provided by the supplier free of charge in case of quality problems.

Why Choose Us?

Our products are exported to more than 70 countries and regions such as the United States, Russia, India, Brazil, Africa, Europe and Southeast Asia.

- Factory Direct

- OEM ODM

- Fast Delivery

- 1v1 Service

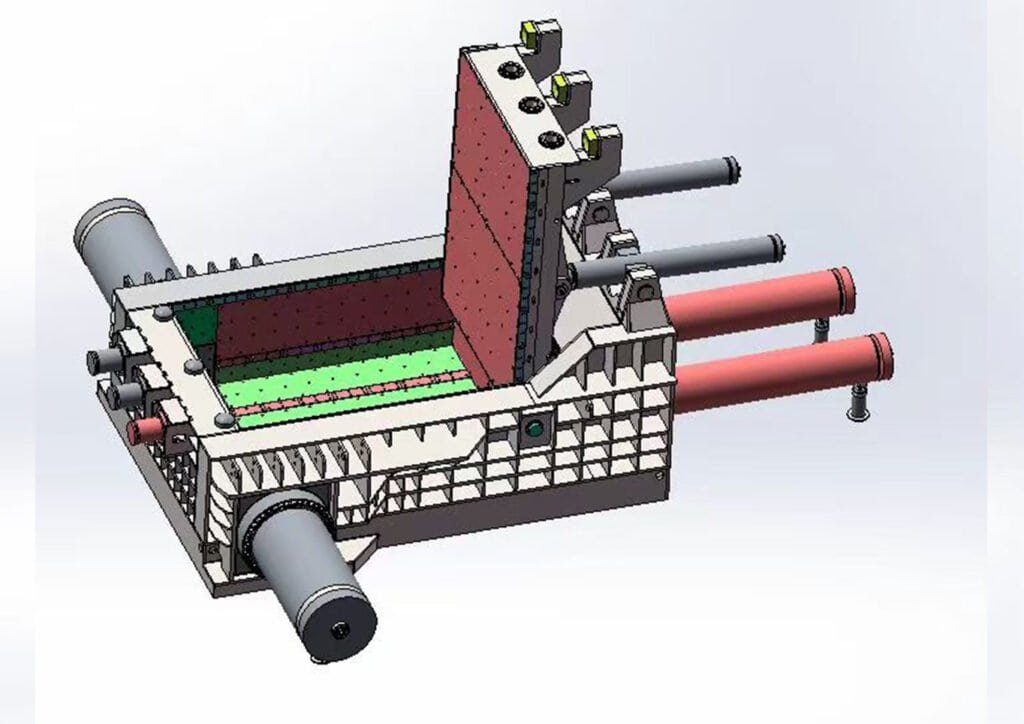

Designed by Experts, Engineered for You

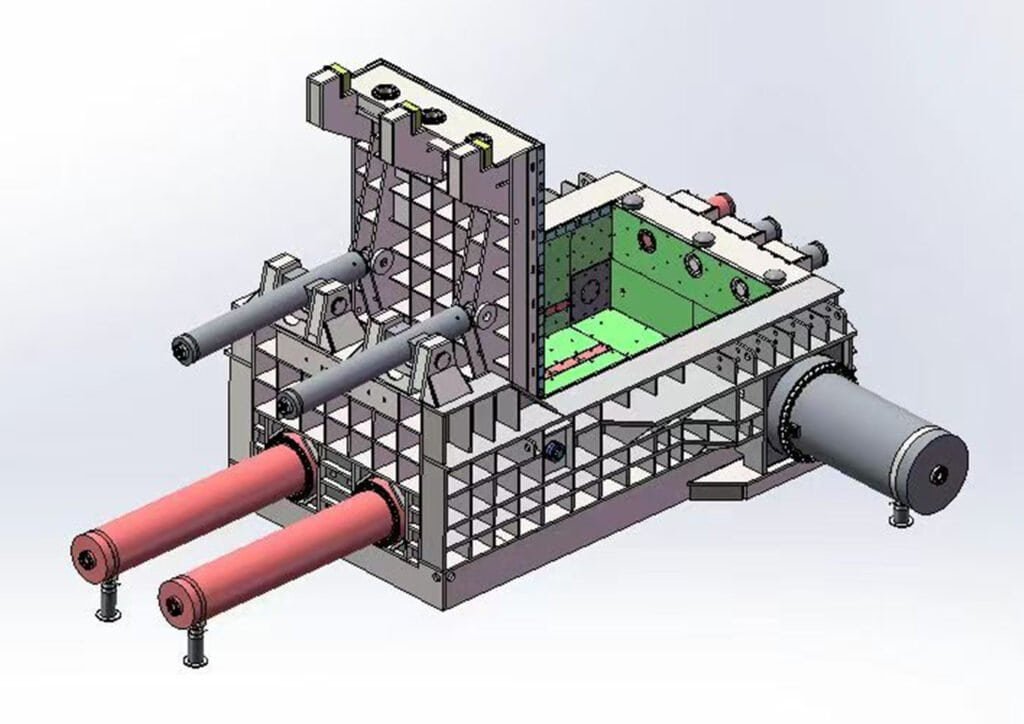

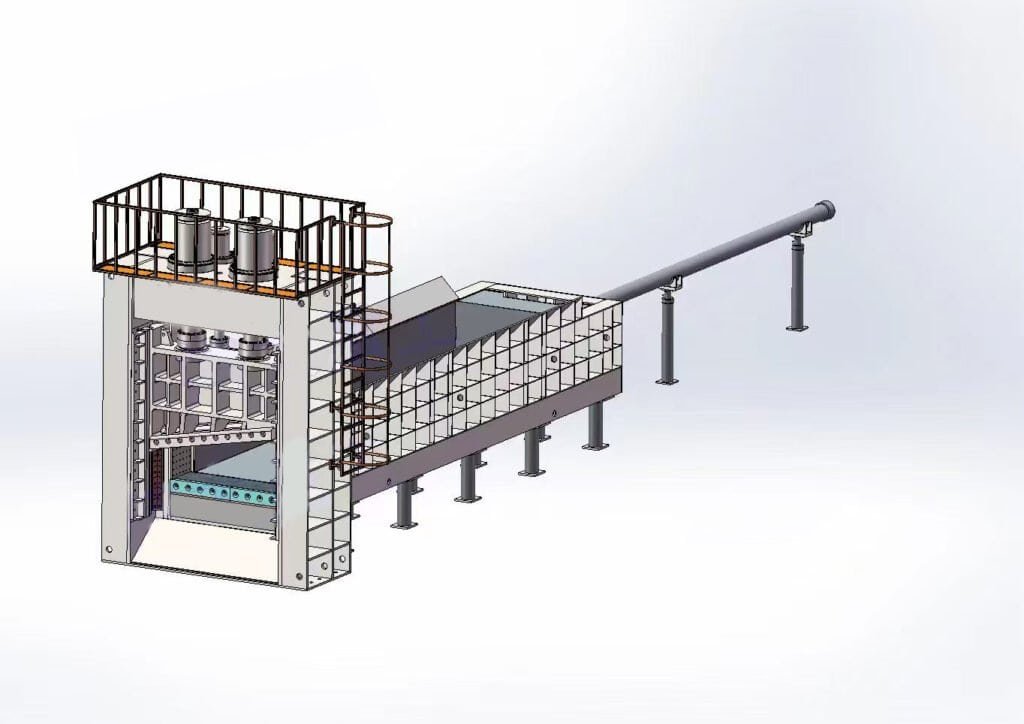

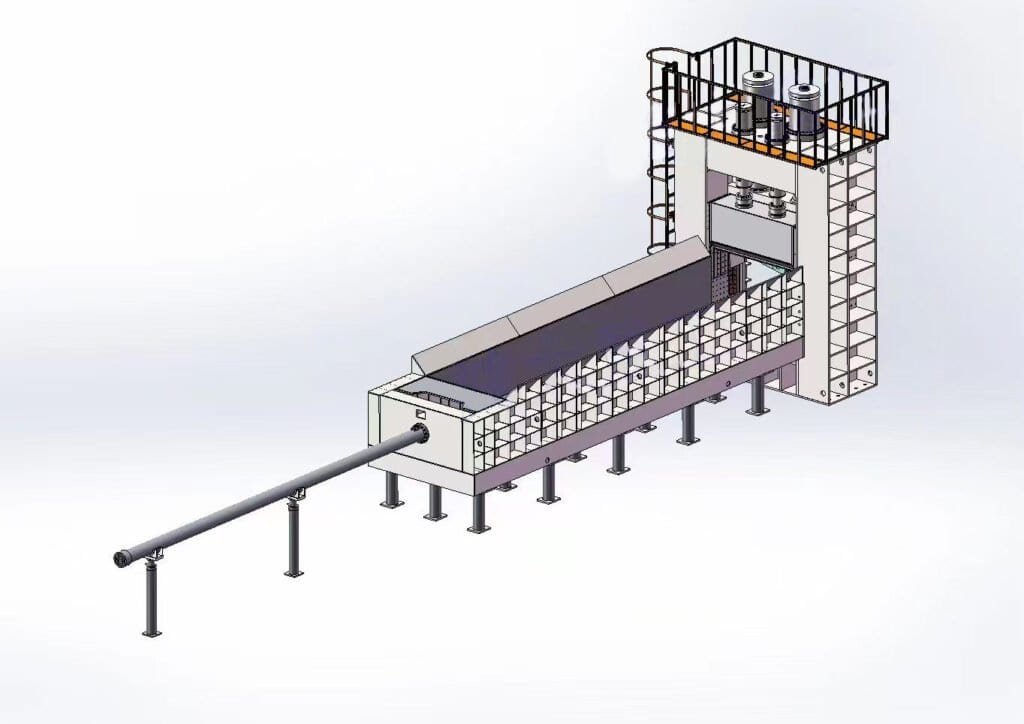

Every machine is meticulously engineered using advanced SolidWorks 3D CAD modeling and FEA structural simulations, ensuring optimal strength, performance, and durability under real-world industrial conditions. We also provide full OEM/ODM customization—our experienced R&D team works closely with you to develop branded or white-label solutions tailored to your market’s exact needs.

About Our Factory

Founded in 2018, our factory has rapidly grown into a trusted name in the scrap metal processing machinery industry. We operate out of a modern manufacturing facility spanning over 38,000 square meters, equipped with cutting-edge production lines and intelligent assembly systems.

- Over 15 Years of Engineering Experience

- Customized Solutions for Your Specific Scrap Volume & Type

- Global Export Experience – Reliable Shipping & On-Time Delivery

- Competitive Factory Pricing, No Middlemen

- Real After-Sales Support & Spare Parts Supply

About Our Products

Each machine is engineered with durability, efficiency, and safety in mind. ISO9001:2008 GB/T9001-2008 certified. Built for 24/7 operation. We manufacture and supply a full range of scrap metal processing machines, purpose-built for industrial use:

Scrap Metal Magnet

1. Fully enclosed structure, good moisture resistance; non-magnetic protection plate made of manganese steelgood solderability, good magnetic insulation, wear resistance, impact resistance.

2. By digesting foreign advanced technology.improving and innovating, and optimlzing by computer design, the product has reasonable structure, light welght, high suctionand low energy consumption.

3. The electrical and mechanical properties of the excitation coll are lmproved by special process. Theheat-resistant grade of the insulatlon materlal is up to class C and the service life is long.

| Model | Electric Current (A) | Cold-State Power (kW) | Lifting Capacity (kg) Steel Ball | Cast Iron | Steel Scrap | Mass (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MW5-70L/1 | 15 | 3.3 | 2500 | 380/200 | 120/100 | 490 | 700 | 800 | 160 | 90 | 30 |

| MW5-80L/1 | 18 | 3.96 | 3000 | 480/250 | 150/300 | 620 | 800 | 800 | 160 | 90 | 30 |

| MW5-90L/1 | 26.6 | 5.9 | 4500 | 650/440 | 250/200 | 800 | 900 | 1090 | 200 | 125 | 40 |

| MW5-110L/1 | 35 | 7.7 | 6500 | 1000/800 | 450/400 | 1350 | 1100 | 1140 | 220 | 150 | 45 |

| MW5-120L/1 | 45.5 | 10 | 7500 | 1300/1000 | 600/500 | 1700 | 1200 | 1100 | 220 | 150 | 45 |

| MW5-130L/1 | 54 | 12 | 8500 | 1400/1100 | 700/600 | 2010 | 1300 | 1240 | 250 | 175 | 50 |

| MW5-150L/1 | 71.2 | 15.6 | 11000 | 1900/1500 | 1100/900 | 2830 | 1500 | 1250 | 350 | 210 | 60 |

| MW5-165L/1 | 75 | 16.5 | 12500 | 2300/1800 | 1300/1100 | 3200 | 1650 | 1590 | 370 | 230 | 75 |

| MW5-180L/1 | 102 | 22.5 | 14500 | 2750/2100 | 1600/1350 | 4230 | 1800 | 1490 | 370 | 230 | 75 |

| MW5-210L/1 | 129 | 28.4 | 21000 | 3500/2800 | 2200/1850 | 7000 | 2100 | 1860 | 400 | 250 | 80 |

| MW5-240L/1 | 154 | 33.9 | 28000 | 4800/3800 | 2850/2250 | 9000 | 2400 | 2020 | 450 | 280 | 90 |

Scrap Metal Baler

1. They are all driven by hydraulic drive, which is stable and safe and convenient;

2. Adopt manual or PLC automatic control mode:

3. The discharge forms are: side flip bag, side push bag, forward push bag or no discharge bag;

4. Installation does not require bottom foot screws, and diesel engines can be used for power in places where there is no power supply;

5. Product specifications and types: The metal baler has 125 ~ 1000 tons and more than 20 specifications for multiple varieties.

It can be used to meet different needs of customers at different levels.

| Atomatic Hydraulic Scrap Copper Steel Waste Metal Recycling Baler | ||||

| Type | Chamber size (mm) | Bale size(mm) | Motor Power(kw) | Oil pump |

| Y81F-200T | 1600*1200*800 | 400*400(300 octagonal) | 22KW+18.5KW | YCY160+YCY80 |

| Y81F-200T | 1800*1400*800 | 400*400(300 octagonal) | 22KW+18.5KW | YCY160+YCY80 |

| Y81F-250T | 2000*1750*800 | 500*500(300 octagonal) | 2*30KW | 2*YCY160 |

| Y81F-250T | 2000*1750*1000 | 500*500 | 2*30KW | 2*YCY160 |

| Y81F-250T | 2500*2000*1000 | 600*600 | 2*30KW | 2*YCY160 |

| Y81F-315T | 3000*2500*1200 | 700*700 | 2*45KW | 2*YCY250 |

| Y81F-315T | 3500*3000*1300 | 700*700 | 2*45KW | 2*YCY250 |

| Y81F-400T | 3000*2500*1300 | 700*700 | 2*45-6 | 2*YCY250 |

| Y81F-400T | 3500*3000*1300 | 700*700 | 2*45-6 | 2*YCY250 |

| Y81F-500T | 3500*3000*1300 | 700*700 | 2*55-4(Double axis) | 4*A7V160 |

| Y81F-500T | 4000*3000*1300 | 700*700 | 2*55-4(Double axis) | 4*A7V160 |

| Y81F-630T | 3500*3000*1400 | 700*700 | 3*45KW-4 | 3*A4V250 |

| Y81F-630T | 4000*3000*1400 | 700*700 | 3*45KW-4 | 3*A4V250 |

| Y81F-800T | 3500*3000*1400 | 700*700 | 4*45KW-4 | 4*A4V250 |

| Y81F-800T | 4000*3000*1400 | 700*700 | 4*45KW-4 | 4*A4V250 |

| Y81F-1000T | 3500*3000*1400 | 700*700 | 5*45KW-4 | 5*A4V250 |

| Y81F-1000T | 4000*3000*1400 | 700*700 | 5*45KW-4 | 5*A4V250 |

| Y81F-1250T | 3500*3000*1400 | 700*700 | 6*45KW | 6*A4V250 |

| Y81F-1250T | 4000*3000*1400 | 700*700 | 6*45KW | 6*A4V250 |

| Y81F-1500T | 3500*3000*1500 | 700*700 | 8*45KW | 8*A4V250 |

| Y81F-1500T | 4000*3000*1500 | 700*700 | 8*45KW | 8*A4V250 |

| Y81F-2000T | 4000*3000*1500 | 700*700 | 10*45KW | 10*A4V250 |

Alligator Shear

1. Hydraulic drive, easy to operate and easy to maintain

2. Working tool port length 600mm700mm800mm 1,000mm 1200mm. 1500mm. 1600mm and other models

3. Install no bottom foot screws. Where there is no power supply, diesel engine can be used as power.

4. The equipment adopts hydraulic transmission. Compared with the mechanical transmission shear machine, it has small size, light weight, low inertia, low noise, stable movement, convenient operation, flexibility, large shear surface and convenient scissor port adjustment.

5. Safe operation and use, easy to achieve overload protection and other characteristics

| Mode | Max Shearing Force (T) | Blade Length (cm) | Total Power (kW) | Shearing Capacity (mm) | |||||

| Square Steel | Round Steel | Angle Steel | Channel Steel | Steel Plate | I-beam Steel | ||||

| Q43-160 | 160 | 700 | 18.5 | 50*50 | 63 | 110*110*10 | 200*75*9 | 25*200 | 100*68*4.5 |

| Q43-200 | 200 | 1000 | 18.5 | 65*65 | 70 | 110*110*10 | 280*82*7.5 | 25*400 | 250*118*10 |

| Q43-250 | 250 | 1200 | 22 | 70*70 | 80 | 160*160*12 | 280*124*11.5 | 20*700 40*300 | 250*118*10 |

| Q43-315 | 315 | 1200 | 37 | 75*75 | 85 | 160*160*12 | 280*124*11.5 | 20*700 40*300 | 250*118*10 |

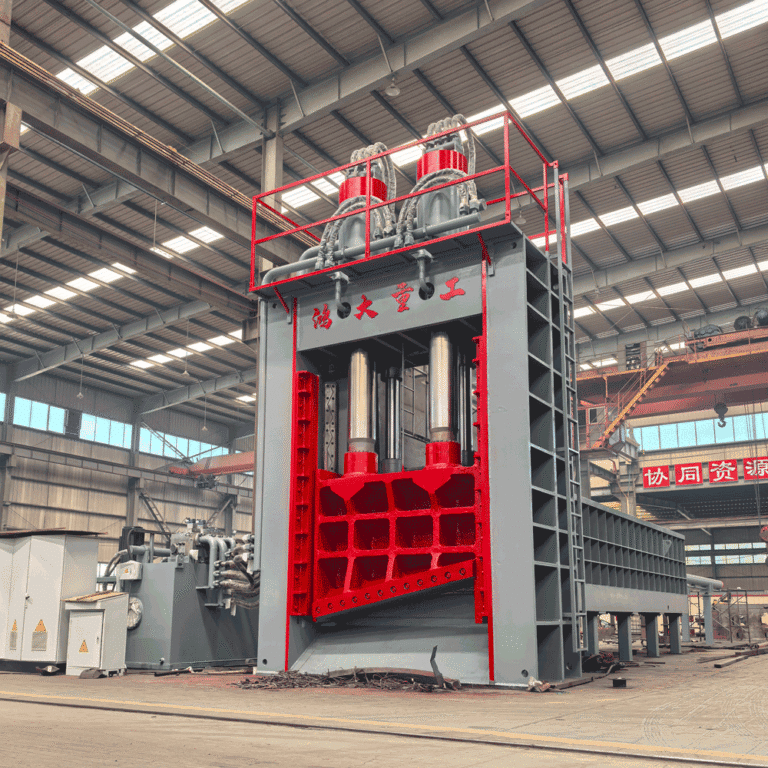

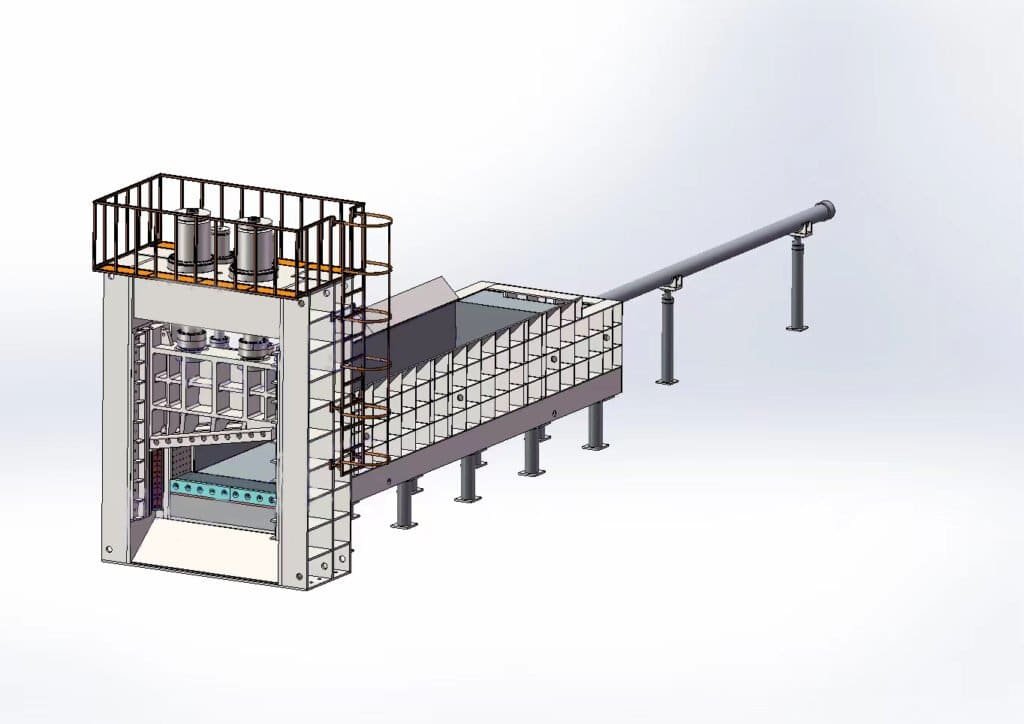

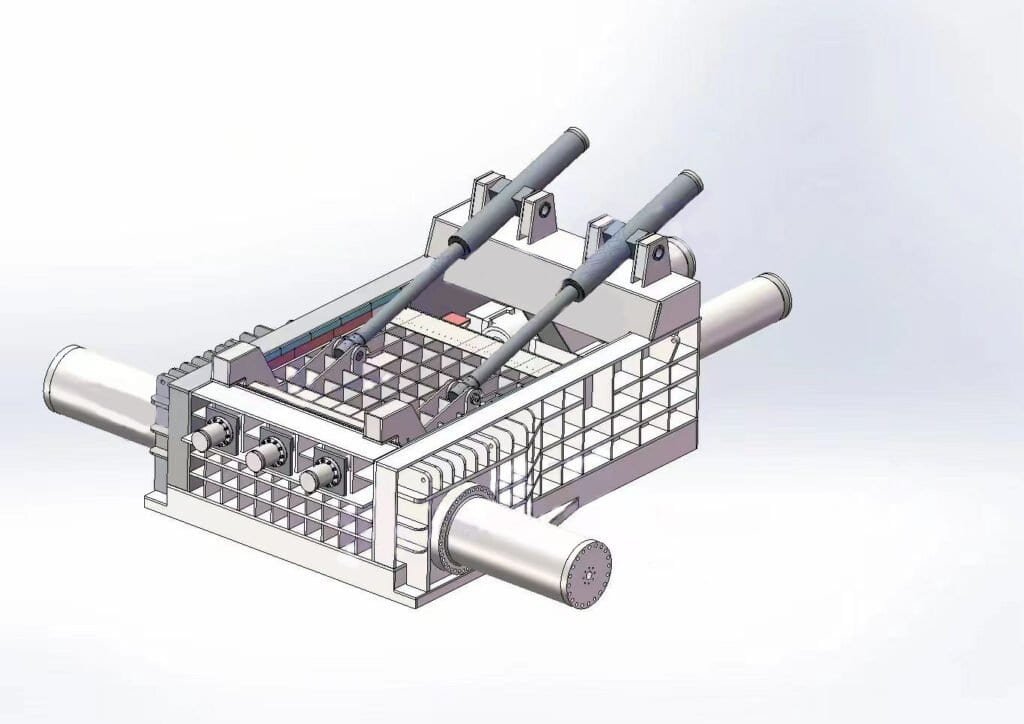

Gantry Shears

1. This equipment adopts hydraulic transmission. Compared with the mechanical transmission shear machine, it has small size, light weight, low inertia, low noise, stable movement, convenient operation, flexibility and large shear surface. The advantages of convenient adjustment of the scissor port are safe to operate and use, and it is easy to achieve overload protection.

2. This equipment has manual, automatic and remote control functions, which is convenient and simple to operate and control.

The scissors port starts and cuts at will in the working process. The well can be cut according to the shear materials. The size of an shear is controlled arbitrarily to achieve high-quality work efficiency.

| Model | Max.cutting force(ton) | Press Box Size(mm) | Cutting Frequency(times/min) | Motor Power(kw) |

| Q91Y-320-1300 | 320 | 6000*1250*600 | 2-3 | 62.05 |

| Q91Y-400-1400 | 400 | 6000*1350*650 | 2-3 | 64.55 |

| Q91Y-500-1600 | 500 | 6000*1550*700 | 2-3 | 82.55 |

| Q91Y-630-1600 | 630 | 7000*1550*800 | 2-3 | 99.05 |

| Q91Y-630-1800 | 630 | 700*1750*800 | 2-3 | 99.05 |

| Q91Y-800-2000 | 800 | 8000*1950*800 | 2-3 | 174.50 |

| Q91Y-1000-2000 | 1000 | 8000*1950*800 | 2-3 | 195.40 |

| Q91Y-1250-2200 | 1250 | 8000*2150*1100 | 2-3 | 293.50 |

| Q91Y-1600-2500 | 1600 | 8000*2450*1100 | 2-3 | 394.60 |

Shandong Horizon Machinery Co., Ltd

12 senior engineers driving continuous innovation

26+ mid-to-senior level managers ensuring efficient operations

150+ skilled hydraulic technicians bringing precision to every machine

10 professional sales teams, each with over 20 dedicated members

Take A Closer Look

What sets us apart is our commitment to delivering smart, high-performance solutions backed by: One of the most advanced R&D teams in the domestic market; Fully integrated, intelligent manufacturing and assembly systems; Extensive field experience and responsive after-sales support

Start Crushing It Today!

Ready to upgrade your scrap metal operation? Let us help you select the right machine for your workflow.

Tel: +8615376202798/+8613695488977